- Johnson Controls

- Insights

- De-Carbonized Cooling and Heating with Absorption Technology

De-Carbonized Cooling and Heating with Absorption Technology

By Albin Fan, Product Manager Asia Pacific, Johnson Controls

We all have a part to play to fight climate change and we can do this together by moving towards a more carbon-neutral footprint. China has announced that it would strive to bring carbon dioxide emissions to a peak before 2030 and become carbon neutral before 2060 to tackle climate change. Singapore launched the Singapore Green Plan 2030 on 10th February 2021. This plan strengthens Singapore’s commitments under the UN’s 2030 Sustainable Development Agenda and Paris Agreement, and positioning us to achieve the long-term net zero emissions aspiration as soon as viable. The heat (cooling and heating) sector represents a major part of the total energy consumption in Asia Pacific region. Decarbonizing the heat sector is imperative to meet the goal of becoming carbon-neutral.

Absorption chillers / heat pumps use water as the refrigerant, yielding zero ozone depletion and global warming potential; Absorption unit operates under vacuum with a few moving parts, quiet and low noise. Absorption technology is truly green, environment-friendly and sustainable.

Absorption chillers / heat pumps transfer energy from waste heat source to deliver de-carbonized cooling and heating for commercial, industrial, district energy and even marine applications. Absorption chillers / heat pumps have been around since 1960s with hundreds and thousands of installations in operation successfully all over the world.

Two major applications of absorption in urban energy sector:

1) CHP Project:

CHP (Combined Heat and Power Supply) is an energy efficient technology that generates electricity and captures the heat that would otherwise be wasted to provide useful thermal energy—such as steam or hot water—that can be used for space heating, cooling, domestic hot water and industrial processes. Two major types of CHP systems:

- Combustion Turbine, or Reciprocating Engine, with Heat Recovery Absorption Unit (Small-medium size)

Combustion turbine or reciprocating engine CHP systems burn fuel (natural gas, oil, or biogas) to turn generators to produce electricity and use heat recovery devices to capture the heat from the turbine or engine. This heat is converted into useful thermal energy, usually in the form of exhaust gas, steam or hot water to drive chillers / heat pumps.

- Steam Boiler with Steam Turbine, with Heat Recovery Absorption Unit (Large Scale)

With steam turbines, the process begins by producing steam in a boiler. The steam is then used to turn a turbine to run a generator to produce electricity. The steam leaving the turbine can be used to produce useful thermal energy. These systems can use a variety of fuels, such as natural gas, oil, biomass, and coal.

Along with the wide applications of CHP, more and more airports, railway stations, hospitals, city center commercial complexes, universities, industrial parks etc. are using absorption chillers / heat pumps for fully utilizing the low-grade heat after power generation. You would probably be surprised to know that the following airports in Asia are mainly or partly utilizing absorption chiller technology for cooling: Both Narita and Haneda Airport Tokyo, Kansai Airport Osaka, Kuala Lumpur Airport, Suvarnabhumi Airport Bangkok, Capital Airport Beijing, and Pudong Airport Shanghai.

2) Renewable Energy Projects Such as Solar /Bio-mass /Bio-gas /Geothermal /Fuel Cell etc.

Solar hot water chiller; bio-mass boiler combined with steam / hot water absorption chiller; bio-gas direct fired chiller, or bio-gas CHP projects; geothermal hot water chillers / heat pumps; and the latest innovative application of hydrogen fuel cell CHP systems.

Johnson Controls and the YORK® brand have been at the forefront of progress and development in absorption technology serving global markets since 1960.

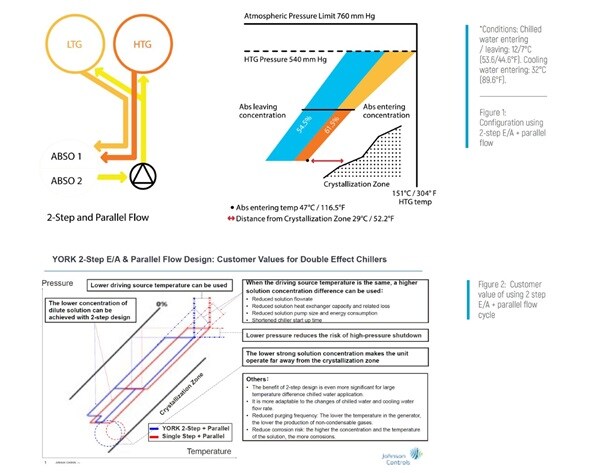

With more than 80 patents recognizing the innovative engineering, YORK® Absorption chillers/heat pumps have a much deeper history when combining decades of proven reliability with the design flexibility of multiple driving heat sources. These sources deliver a truly reliable, highly efficient and resilient solution for more flexible applications with unique features such as patented two step evaporator / absorber and parallel solution cycle for double effect design.

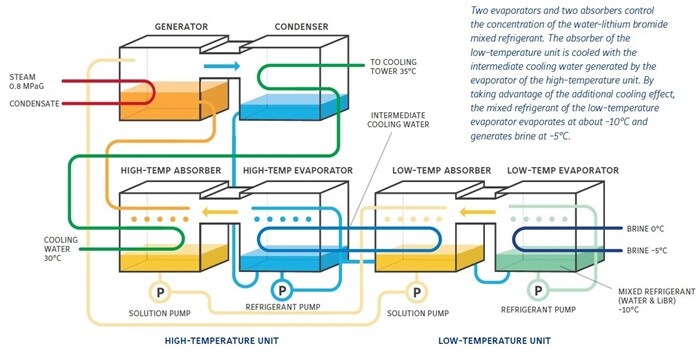

This two-step evaporator / absorber design has an effective vapor-pressure difference in both the upper and lower sections; when compared to the conventional cycle, enhances single-effect absorption chiller performance by improving crystallization protection, along with enabling the use of lower-grade hot water or low-pressure steam as a driving heat source. These benefits cross over to a double-effect absorption chiller that takes advantage of parallel flow cycle combined with the two step E/A structure, with unprecedented lows in lithium bromide solution concentration during operation, which minimizes crystallization risks and provides performance benefits. (See Figure 1 and 2)

The combination of two step E/A technology with double effect parallel flow cycle is accomplished with simple construction and the end result is greater application flexibility, plus an optimum balance between reliability and efficiency, which make these advanced absorption chillers / heat pumps designs more attractive for more applications than ever before.

Furthermore, flexibility has increased dramatically in recent years by Johnson Controls. Below are some examples:

1) Low Leaving Chilled Water Temperature

The innovative YORK® YHAU-C-LL absorption chiller enables -5°C refrigeration without ammonia using an advanced two-step evaporator and absorption cycle. As a result, YHAU-C-LL absorption chillers provide an environmentally friendly and energy-efficient solution where refrigeration is needed below the freezing point — such as food processing and storage applications.

2) Marine Absorption Applications

The use of absorption chillers on a passenger vessel further illustrates the evolution of YORK® technology. Absorption chillers have successfully overcome the vessel’s rolling, pitching and tilting, demonstrating true operating flexibility.

This article was first published in the APUEA Magazine issue 11 September 2021 (www.apuea.org)

.jpg?la=en-SG&h=320&w=720&hash=8335BA7A0D096E90165B06350796126C)

.png)